Our park

of machines

Our fleet of 350 machines allows us to produce parts from Ø 0.30 to Ø 6.50 mm for a maximum length. 500mm.

The series range from 10,000 to several million pieces.

Request an offer

Our services

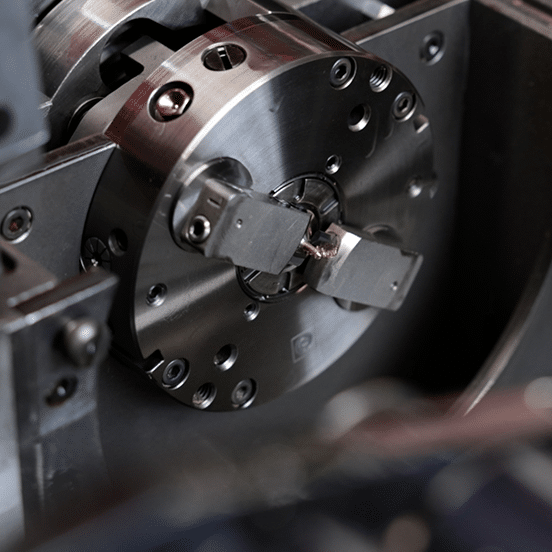

245 escomatic machines

More than 245 machines turning escomatic type allow our teams to produce medium to large series of parts. machining is possible from material wire without nipple. Between 2005 and 2018 we added around 50 JB4 type machines. Most of our own machines are less than 20 years old. We work to constantly upgrade the machine park thanks to our service. research and development.

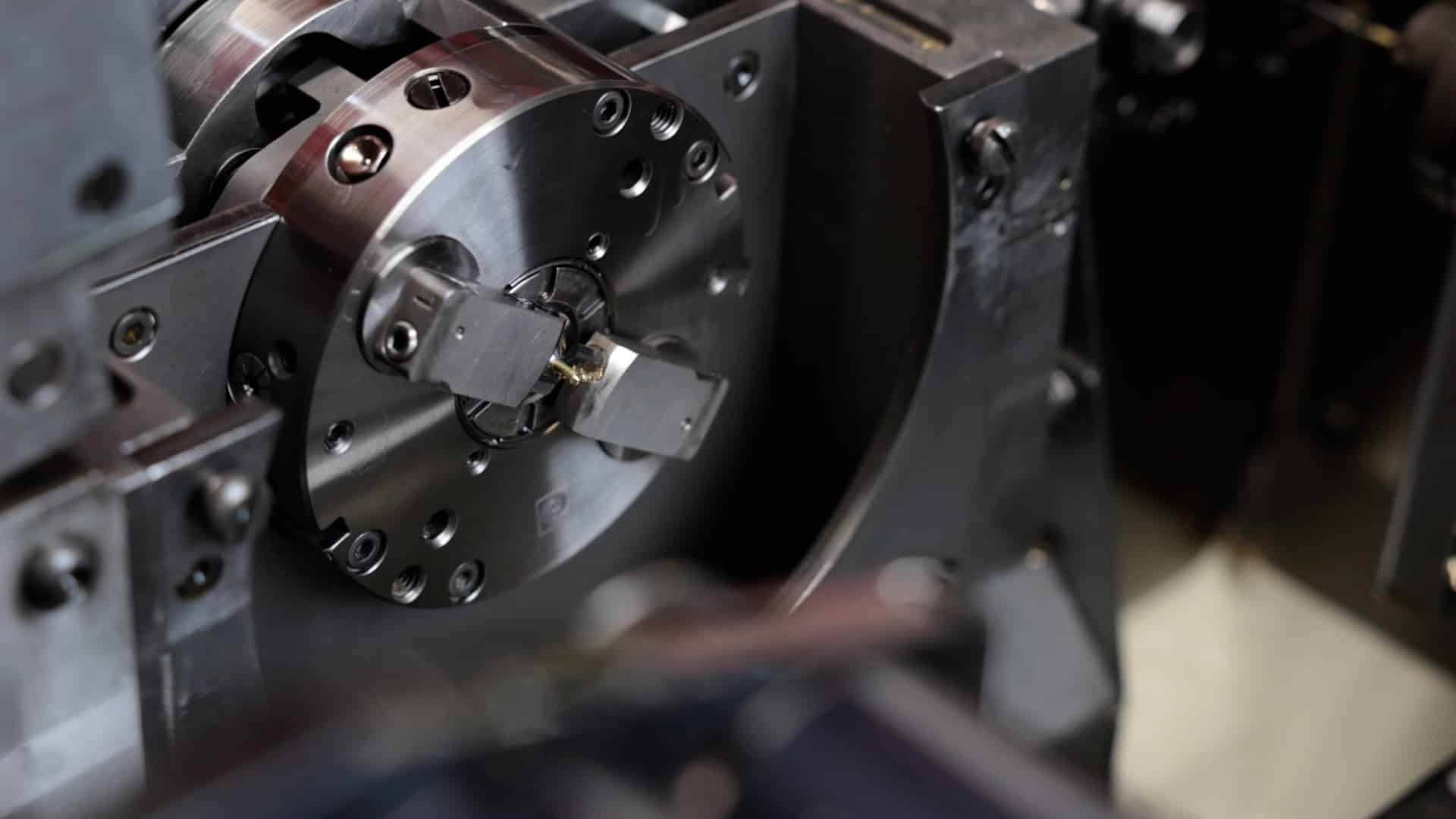

30 bar-type bar turning machines

More than 30 machines turning bar type are in production within our machine park.

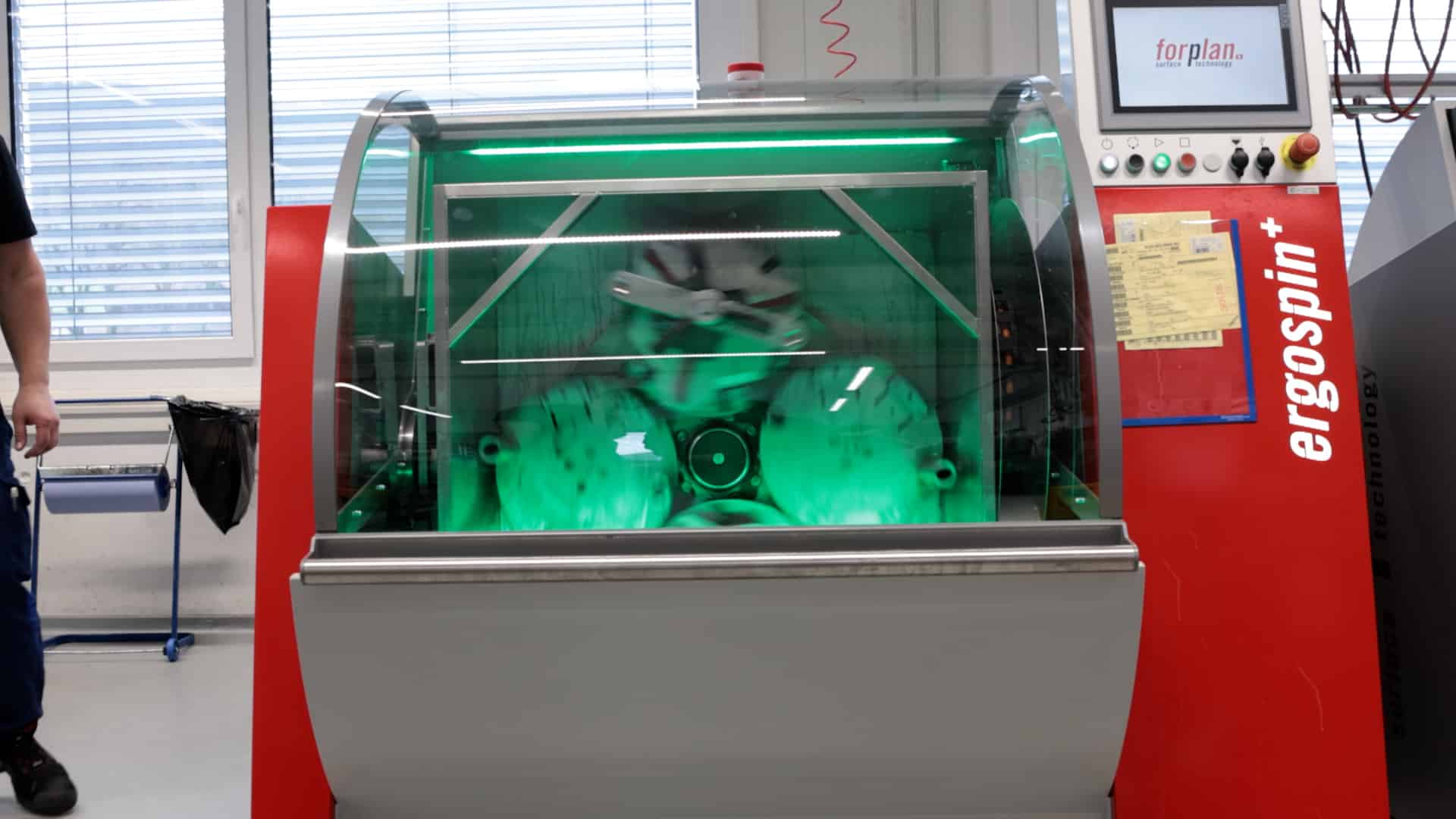

42 polishing and washing machines

We guarantee a quality of finish perfect thanks to efficient washing machines, an efficient polishing workshop and a network of partners specialized in heat and surface treatments.

40 sorting machines ø default

On request and on the basis of defined criteria, in order to guarantee a perfect result for our customers, we carry out specific sorting to achieve zero defects.

Examples of achievements

We produce different families of parts, where individual parts differ by one parameter (usually length), and flexibly adjust the quantities of each production.

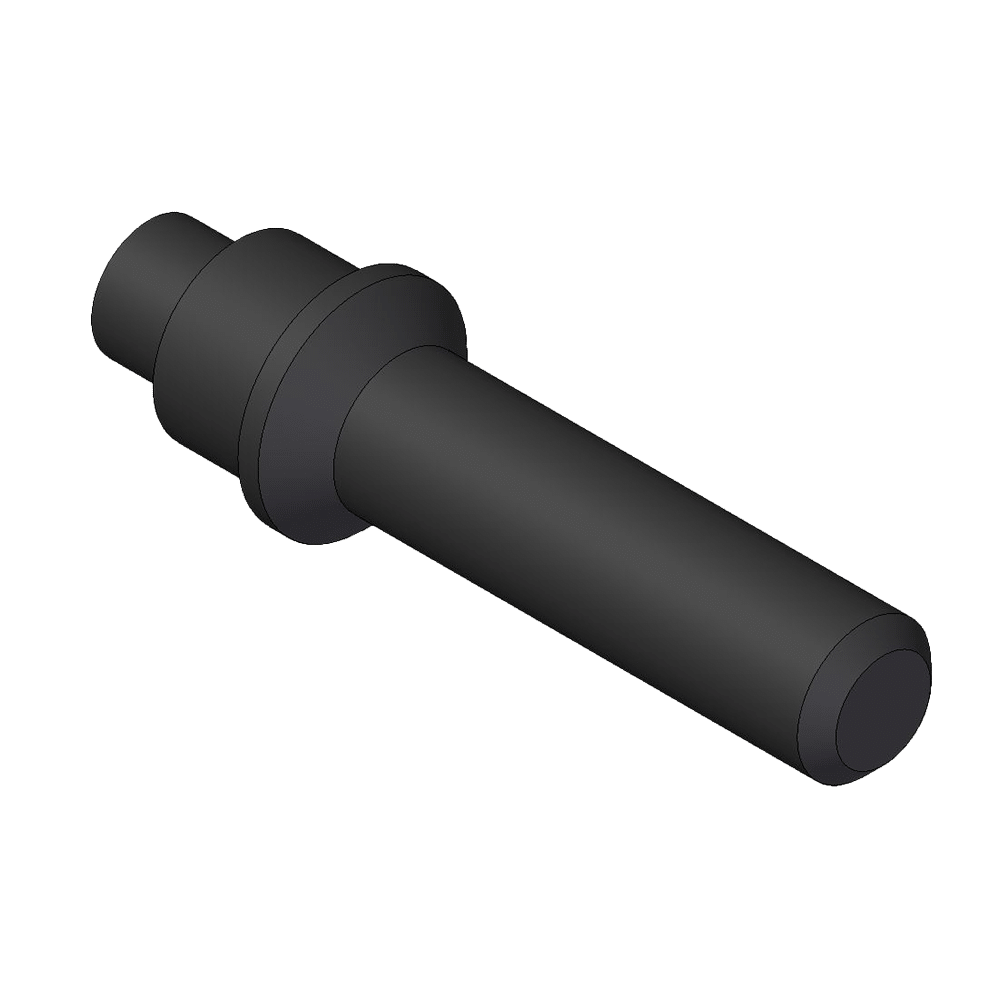

Part for pruning shears, blackened

ø 5,400; L 19,000 mm

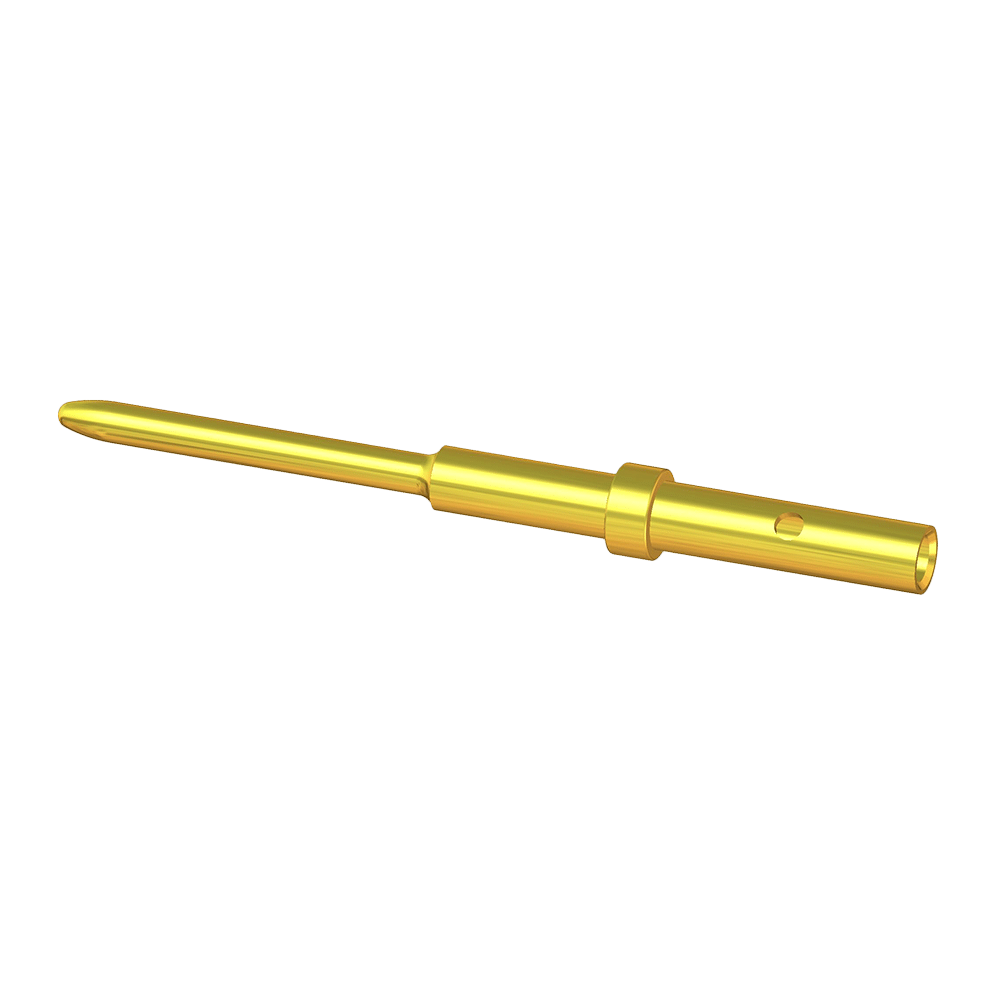

Annealed plug, gilded with color code

ø 1,730 mm; L16,700 mm

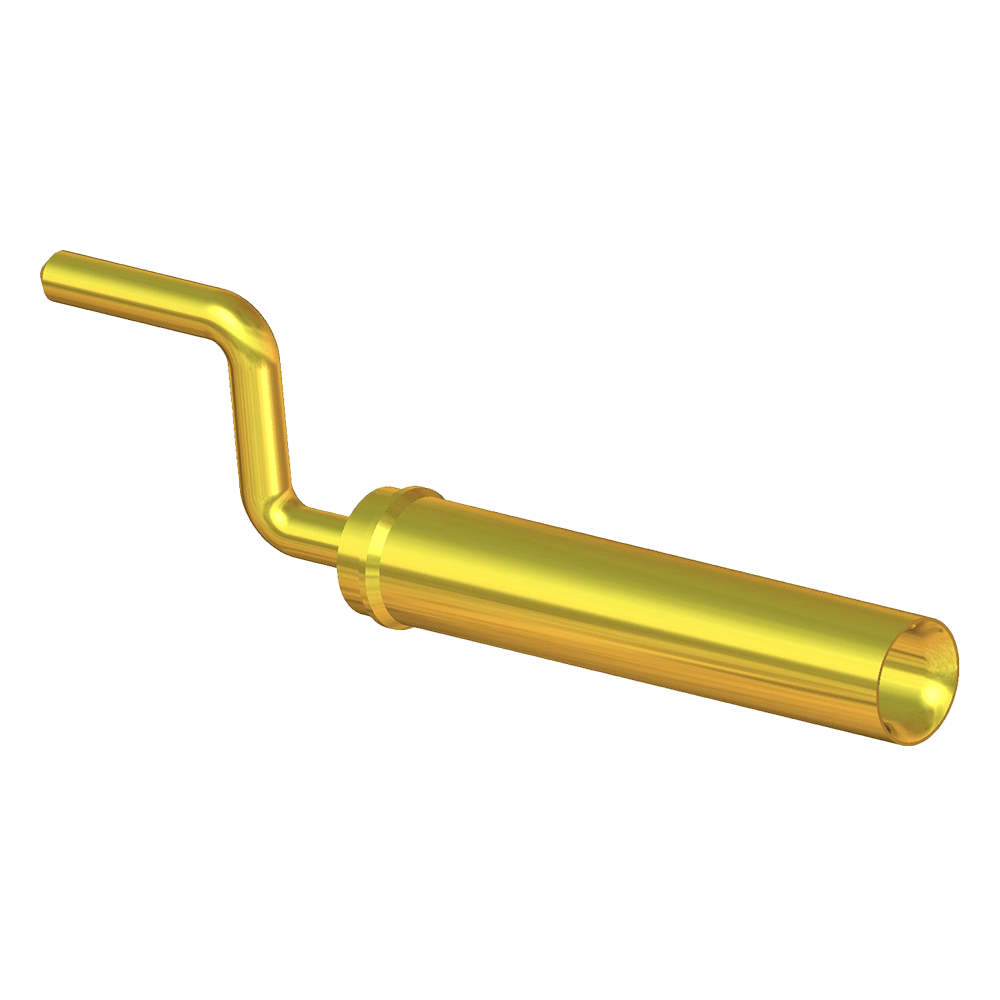

Sheet with milling and folding, gold

ø 1,650 mm; L 12,500 mm

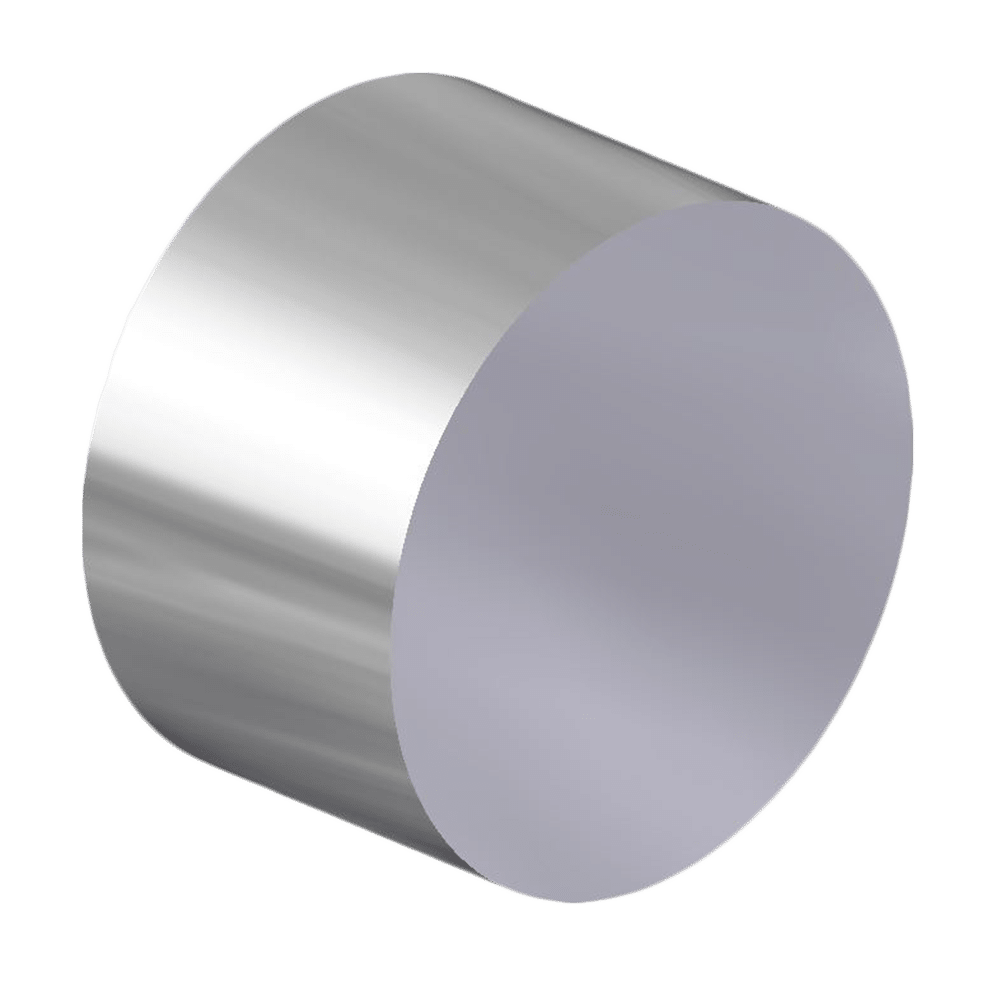

Distance pin in ARCAP® AP1D

ø 2,000 mm; L 1,200 mm

Machined materials

As part of our production, we attach particular importance to respecting Swiss quality standards. To do this, we meticulously respect the materials requested for your project.